wire edm machine how it works

The spark takes place in deionized water. Free Shipping on Qualified Orders.

Wire Edm Machining Cutting Services Moon Tool

EDM is an abbreviation for Electrical Discharge Machining.

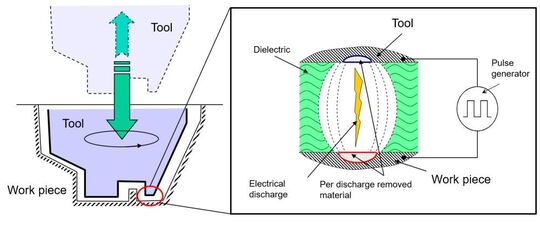

. To begin the cut the wire must cut into the metal from the side or through a hole that is drilled into the center of the metal. The term EDM stands for Electrical Discharge Machining. Material is removed from the work piece by a series of rapidly recurring current discharges between two electrodes separated by a dielectric liquid.

The Electrical Discharge Machining EDM is an unconventional. We added this attachment onto. In the early days it was difficult to manufacture parts with fine shapes and tight tolerances using conventional machining techniques but nowadays parts with tight tolerances can be achieved by the electric discharge cutting process using wire cutting.

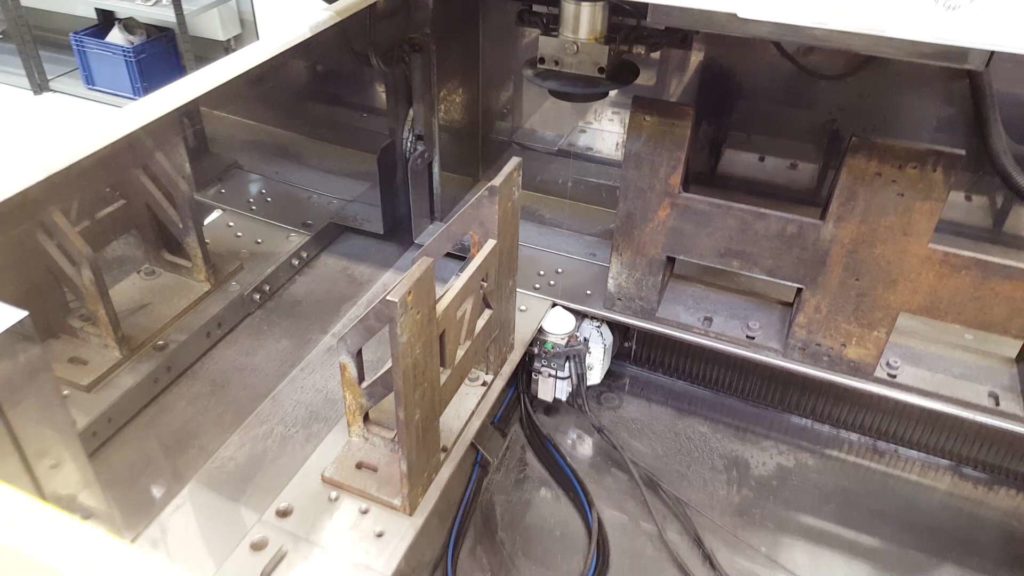

Be sure you will get the best out of more than 4000 used machines and tools. The wire-cut EDM process was introduced in the 1960s and the first CNC EDM machine was created in 1976. Ad For creating more complex geometries w high accuracy.

In EDM machine the material is removed by rapidly recurring repeating. For example a. A16b 1000 0210 Fanuc Edm Machine Board Memory Module Cnc Machine Tools Ram Module Uses is commonly known as wire manufacturing wire burning or wire erosion.

The distance between the guides can be adjusted to accommodate the thickness of the workpiece. DIY Wire EDM is finally a reality. Due to the inherent properties of the process Wire EDM can easily machine complex parts and precision components out of hard.

They will then instruct the machine to go ahead and. 40 Years of Quality Value and Service. The cutting wire is stretched tight.

Ad Shop Devices Apparel Books Music More. A wire EDM machine looks like a bandsaw that has a wire for a blade. There are three types of EDM.

Short interesting video on the fundamentals of the electrical discharge machinin. With wire EDM we can cut any. Basic introduction to the wire EDM and high-speed small hole EDM processes.

You all know about conventional machines like lathe milling grinding or drilling where the cutting tool is always harder than the work-piece. He was an English physicist. EDM is an abbreviation for Electrical Discharge Machining.

Are all part of the equation to design and fixture the work. The wire is energized as it passes across a. The use of thin wires to cut objects can also be referred to as wire erosion wire burning EDM.

A simplified overview of the process. EDM typically works with materials that are electrically. Sinker EDM Wire EDM and Fast hole drilling EDM.

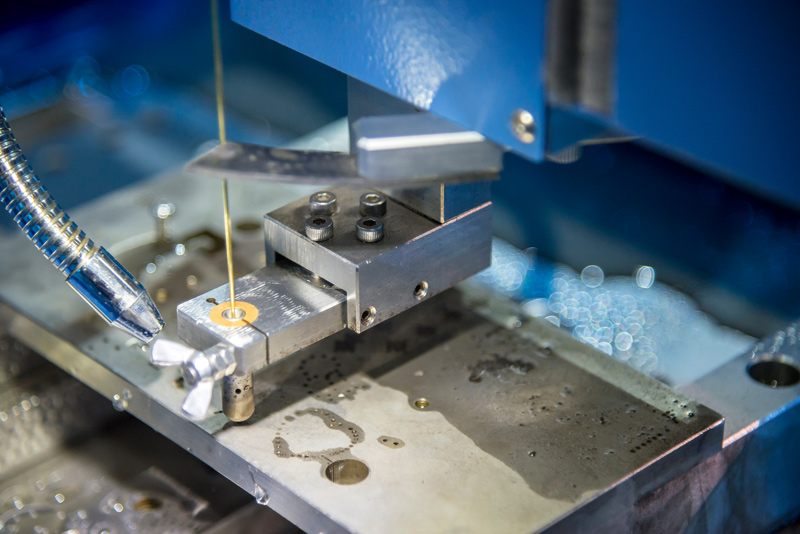

Wire electrical discharge machining EDM is a process of metal machining in which a tool discharges thousands of sparks to a. In this type the wire is used as an electrode and the wire is continuously fed from. Wire EDM also known as wire electrical discharge machining WEDM or wire-cut EDM involves using a thin single-strand metal conductive wire like brass along with de-ionized water allows the wire to cut through metal with the heat from electrical sparks.

The EDM wire is tinymeasuring only 0010 to 0012and it may be made of brass or other materials for specific applications. 1 A wire EDM machine uses a thin piece of. This has been on our DIY CNC machine radar for quite some time and finally we have done it.

Types of EDM machine. Wire Cut EDM uses an electric current to cut through metal to make the desired shape. It shoots tiny lightning bolts through a water or oil insulator called a dielectric using electrical energy to blast away tiny bits of metal.

A tightly controlled sequence of electrical discharges. A wire EDM machine uses a thin piece of electrically charged wire as a saw blade to cut any metal which will conduct electricity. Also the cutting tool applies the force to remove the material from the work-piece during machining.

As the spark jumps across the gap material is then removed from the work piece and the electrode. Wire EDM uses an electrically charged strand of wire fed from a reel and moved through upper and lower guides. How It Works.

The water helps cool the material being cut and also helps wash away metal as it is freed. Wire EDM machining also known as spark EDM works by creating an electrical discharge between the wire or electrode the workpiece. The Electrical Discharge Machining EDM is an unconventional.

The basic electrical discharge machining process is really quite simple. Electrical discharge machining EDM also known as spark machining spark eroding die sinking wire burning or wire erosion is a metal fabrication process whereby a desired shape is obtained by using electrical discharges sparks. Material gradealloy temper thickness finish shape tolerances etc.

We use a special CAD program called Espirit that interfaces with the EDM machines to create exacting programs for our operators to run the machines that make the parts to the customers exacting specifications. Simply put you can think of wire EDM as a highly accurate bandsaw one with a blade wire measuring 0010 or so in diameter. A wire EDM machine is a type of CNC machine that can move along four independent axes to generate taper cuts.

Wire EDM also known as WEDM in the wire EDM process a thin single-strand wire works as the electrode and the wire are continuously fed from the automatic feed with the spool during the process the electrical discharge is created between the wire and workpiece as the spark moves across the gap the material is then removed from. Wire EDM machining works by creating an electrical discharge between the wire or the electrode and the work piece. EDM is an abbreviation for Electrical Discharge Machining.

Types of Electrical Discharge Machining. It was first observed in 1770 by Joseph Priestley. Electrical Discharge Machining EDM is a non traditional machining and electro thermal process in which material from the workpiece is removed by using electrical discharges sparks.

The wire is energized as it passes across a power contact at the top and bottom. Ad At Surplex you will find used machinery and industry equipment at best prices. Wire EDM also known as WEDM in the wire EDM process a thin single-strand wire works as the electrode and the wire are continuously fed.

Wire Cutting Electrical Discharge Machining. A wire EDM machine is a type of CNC machine that can move along four independent axes to generate taper cuts. How it Works Simply put you can think of wire EDM as a highly accurate bandsaw one with a blade wire measuring 0010 or so in diameter.

An electrical discharge spark is created between two electrodes solid electric conductors. How Electrical Discharge Machining Works.

How Does Wire Edm Work Laszeray Technology Llc

What Is Wire Edm Electrical Discharge Machining Xact

What Is Electrical Discharge Machining And How Does It Work

Wire Edm Machining Wire Cutting Services In China

Wire Edm For Cutting Metal 3d Prints

Wire Electric Discharge Machining Wire Edm Youtube

Edm Past Present And Future Asia Pacific Metalworking Equipment News Manufacturing Automation Quality Control

Wire Electrical Discharge Machining An Overview Sciencedirect Topics

News Brass Wire For Wire Cut Machine Die Sinking Electrical Discharge Machine Fully Automatic Wire Cutting Machines Novick Digital Equipment Co Ltd

Cnc Wire Cut Cnc Wire Edm Wire Edm Wire Edm Machine Working Principle Youtube

How Wire Edm Works Missouri S Wire Edm Machine Shop

What Is Wire Edm A Guide To Wire Electrical Discharge Machining

Wire Edm Also Wire Erosion Is A Shaping Manufacturing Process Cutting Process Which Works According To The Principle Of Spark Erosion

Wire Cut Edm Machine Wire Cut Edm Machine Working Principle Shorts Youtube